"programming" the prototype

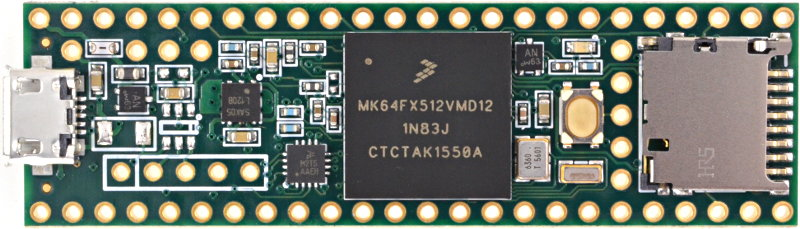

Now that the prototype shows signs of coming to life, it is time to consider how to animate it. The axles are rotated and lifted from the "21st century" section on the bottom that is filled with stepper motors controlled with a PJRC "Teensy 3.5" microcomputer. Here are comments from the source file of a motion script interpreter I have written for it: The following axles are implemented in this first prototype: C carry sectors for adding 1 F the anticipating carriage digit wheels FC the connector pinion for above to FP FP the fixed long pinions FPC the connector pinion for above to either A1 or A2 MP the movable long pinions MPC the connector pinion for above to either A1 or A2 A1 the upper number i...