gear backlash woes

Changing the long pinion meshing to be to the inner gear solved the problem of bogus multiplication by 1.35. But now there is another problem: random subtraction of 1.

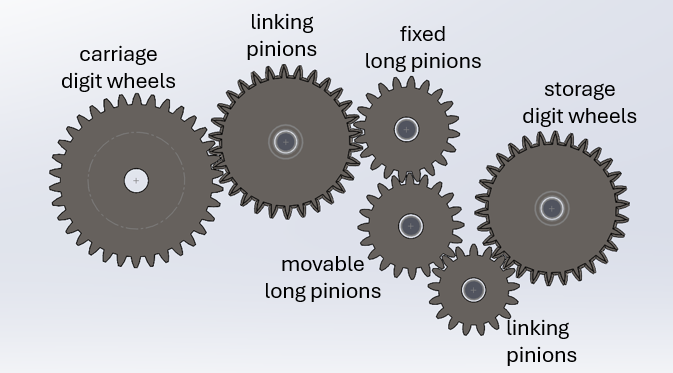

The root cause is excessive gear backlash. When configured for addition there are four gears between the digit wheel that is "giving off" a source digit and the digit wheel in the adder ("anticipating carriage") that receives it.

If I hold the destination carriage wheel I can wiggle the source wheel almost a complete tooth -- which is a full digit -- without it trying to move the destination. In doing a transfer I can get it to work correctly by "preloading" the gear train. But if I don't do that, then the first digit being given off might be absorbed by the slop in the gear train. This is clearly a major problem.

There are three contributors to the backlash:

- The center-to-center spacing of the shafts is slightly larger than the gears were designed for, which had to be done to make meshing smooth. The precipitating issue is probably that the shafts are not adequately vertical and parallel.

- The 3D-printed plastic gears are sloppy, with a tolerance of about 0.5mm. or about 20 mils (thousandths of an inch). Any decent machinist, including those in Babbage's time, can consistently produce metal parts to 5 mils.

- I lock and "quantize" the rotational position at the beginning and ending digit gears, but at none of the intermediate gears. Babbage talked about locking at every second or third gear in a train.

Tim Robinson says "I don't recall ever seeing Babbage say specifically how much backlash there should be, and it would be hard to determine by looking at drawings. However, given his general pursuit of perfection in the fabrication, I would have thought he would be expecting only a quite small amount."

Well, my preferred fabrication techniques do not permit the pursuit of perfection. I will try to improve #1 above, but I am also exploring what changes to the parameters will make the design more tolerant of imperfection.

My initial proposal is to change from 1 gear tooth per digit to 2, which will greatly reduce the deleterious effect of backlash, and also to change to slightly finer teeth. Here are the current and proposed digit wheel parameters:

| old | new | |

|---|---|---|

| teeth per digit | 1 | 2 |

| DP (diametral pitch) | 10 | 12 |

| diameter in inches | 3.000 | 3.333 |

| number of 0..9 cycles | 3 | 2 |

| number of teeth | 30 | 40 |

I also propose not using the gear teeth for locking, but instead adding separate one-per-digit locking teeth. That provides much more opportunity for correction. (Babbage experimented with both ways in the various Plans.)

With those changes, the top half of a pair of digits in a number cage would look like this:

Comments

Post a Comment